Teleoperated robots and hardware agnostic robotics platforms are nascent trends with huge future potential

The global pandemic and labor shortages mean robotics adoption and workforce automation continue to dominate the agenda of industrial and manufacturing firms. In its latest report, global technology intelligence firm ABI Research assesses the latest trends in the robotics industry that further propel the adoption of automated solutions, namely teleoperated robots and hardware agnostic robotics platforms.

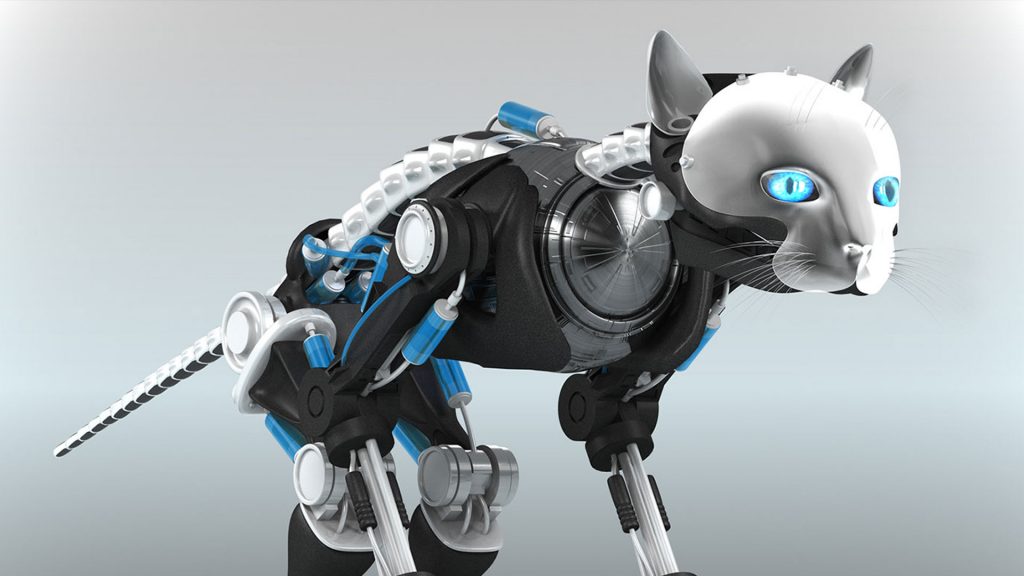

The Covid-19 pandemic has led to a significant uptick in automated solutions demand in commercial and industrial sectors. Unsurprisingly, 2021 has been a good year for Automated Mobile Robots (AMRs) and Small Unmanned Arial Systems (sUASs). However, market demands are not limited to these two form factors. Teleoperated robots are becoming more and more popular, driven by field applications, including high altitude material handling, non-destructive testing, and inspection of critical infrastructure, as well as field construction. Field robotics application revenue is expected to reach US$29 billion by 2030.

“The concept of teleoperated robots is nothing new,” says Lian Jye Su, Principal Analyst, Industrial, Collaborative, & Commercial Robotics at ABI Research. “Remotely operated underwater vehicles (ROVs) and sUASs are most common examples of teleoperated robots. However, these robots have low dexterity and flexibility and are often confined to specific tasks. Newer teleoperated robots, like Guardian XT from Sarcos Robotics, feature high agility and mobility, high bandwidth 5G connectivity, and can be equipped with various end-effector tools. In addition, end users can customize the teleoperated robots for a wide range of complex operations.”

Another nascent trend in the robotics industry is the emergence of hardware-agnostic robotics platforms. As end-users are constantly looking for more sophisticated robotics hardware to automate more workflows, they need to deploy different types of robots. Unfortunately, most, if not all, of these robots come from different vendors. “At the moment, most robots are designed to operate as independent devices. The fragmented landscape of robots used in workflow automation makes managing them through a single software, such as warehouse management system (WMS), or a common cloud platform a very complicated challenge,” Su explains.

End users seek software platforms to facilitate large-scale rollouts through common development, rapid onboarding, orchestration, and maintenance. Hardware agnostic robotics platforms aim to resolve this challenge by providing a single platform that can accommodate all robots. Key players in this space include Augmentus, Energid, Formant.AI, Freedom Robotics, Intrinsic, and MOV.AI. Aside from the tasks mentioned above, they also offer motion planning templates, real-time simulation environments, integration of Machine Learning (ML), and digital twin synchronization to all types of robots and components. With these developments, the maturing robotics software market will experience 17-fold growth in the next ten years.

“Another important feature of these platforms is their compatibility and support for Robot Operating System (ROS) and ROS 2. ROS software packages have been widely adopted in the industry. Compatibility with ROS is critical for roboticists and application developers as it minimizes time spent on redesign and reconfiguration and ensures quicker time-to-market,” concludes Su.

These findings are from ABI Research’s Nascent Trends in Robotics: Teleoperation, Platformization, and Consolidation application analysis report. This report is part of the company’s Industrial, Collaborative & Commercial Robotics research service, which includes research, data, and analyst insights. Based on extensive primary interviews, Application Analysis reports present in-depth analysis on key market trends and factors for a specific technology.